Your Ultimate Guide to Choosing and Using Paving Slabs

When it comes to transforming your outdoor space, the journey of selecting the perfect paving slabs is as exciting as it is rewarding. Whether you are planning a serene patio retreat, a functional garden path, or a sophisticated outdoor entertainment area, the right paving slabs can elevate your space to new heights. This guide will take you through the essential steps and considerations in choosing, buying, and using paving slabs.

The Journey of Buying Paving Slabs

Understanding Your Needs

Before exploring into the vast array of options, it is crucial to define the purpose of your project. Are you creating a patio for relaxation, a pathway through your garden, or a new driveway? Having a clear idea of how you intend to use your new patio will make the paving selection process that little bit easier.

Exploring the Types of Paving Slabs

Natural Stone Paving Slabs: These slabs — sometimes referred to as 'paving flags' — are available in sandstone, limestone, granite and slate, and offer unique textures and natural beauty. They are perfect for creating a timeless, elegant look in your outdoor spaces.

Natural stone varies in colour, sizing, cost, and maintenance levels. Natural stone has been used as a paving material for thousands of years, and it adorns villages, towns, and cities across the globe. London Stone source natural stone from India, Egypt, Brazil, China, and Germany, as well as indigenous stone quarried in the UK.

Modern styling requirements mean that natural stone paving is now often substantially fabricated into sawn (or smooth) paving slabs, to give a contemporary finish, seen often in sandstone, limestone, and granite. 'Riven' (hand-cut) options are synonymous with a more rustic finish and are found across sandstone, slate, and limestone.

Natural Stone is not only available as standard 'paving', London Stone supply several complementary products in natural stone that open a wealth of design opportunities, from stone pavers, cobbles and setts, plank paving, paving circles, and vertical cladding to name but a few.

Porcelain Paving Slabs: Known for their minimal maintenance and high durability, porcelain slabs — sometimes referred to as 'outdoor tiles' — are an excellent choice for modern patios that call for a sleek finish.

Porcelain is created from natural materials — clay, feldspar, kaolin, and quartz — and is moulded into square or rectangular shaped paving slabs, and then fired at temperatures of up to 1240℃, making it extremely robust. London Stone source porcelain paving slabs from Italy and India, ensuring high quality and competitive pricing. London Stone also offer a free 10-year homeowner guarantee with our porcelain paving to give our clients complete peace of mind.

Being a factory-made material, porcelain can meet modern demands of minimal maintenance and consistent style. Although any outdoor material requires ongoing maintenance, porcelain is manufactured to withstand natural elements such as sunlight, frost, and will not develop a patina, like natural stone will, over time. When cleaning porcelain paving tiles with the right chemicals, you should be able to achieve a 'just laid' look, repeatedly.

Porcelain has the unique ability to be available as off the shelf large format slabs and wall cladding, giving you a new realm of design possibilities.

Clay Paving: Durable and versatile, clay paving bricks are ideal for both contemporary and traditional designs. Often used to create winding paths, driveways, and to border patios of larger natural stone or porcelain paving, clay pavers can also be used to create beautiful terraces.

Sourced from The Netherlands and Belgium, clay is a centuries-old paving material, that is manufactured from — as the name suggests — clay, which is baked at a hot temperature in brick-shaped moulds. It has a lifespan of over 100 years, and requires minimal maintenance once laid. Unlike concrete block paving, clay bricks retain their colour, and will not fade over time.

Clay paving is available in a wide range of colours and sizes and is usually laid on a non-rigid sand screed base. Kiln-dried sand is then swept into the narrow joints to prevent lateral movement of the "clays" ensuring an installation that stands the test of time. With several laying patterns available, as well as being available as facing bricks, clay pavers are a highly adaptable material.

Paving Colour Variation & Texture Close-ups

When choosing your paving material, it is important to understand that some products contain colour variation, while others are more colour consistent.

Stone paving slabs, by their disposition, possess natural colour variation including veining, striations, fossil-type markings, and ammonites, to name but a few. Each slab is unique, and certain materials have more colour variation in them than others. Sawing natural stone can make the colours more consistent, but that is not always the case. You will find extensive image galleries for all our paving materials in situ on each product page, along with natural variation information.

Porcelain paving is far more colour-consistent than natural stone. However, due to the manufacturing process of porcelain tiles, each batch does vary in colour from the next. We recommend making a note of your porcelain batch when delivered, in case you add to your project in the future. Within each type of porcelain paver there are several different 'tile prints', enabling seamless laying, without repeating patterns.

Clay Pavers, meanwhile, contain variation within each brick, but the amount of colour variation differs between each product type. Clay paving like Lucca, from our Kessel Garden Range, has minimal variation, whereas Cotswold bricks from our Cottage Garden range are more varied, to give a rustic, more traditional finish.

Head over to our YouTube channel, where we have created in-depth videos of our paving materials so that you can learn more about the surface texture and edge profiles of our slabs.

You can also order free samples online across the entirety of our range, or view materials in one of our nationwide showrooms, to ensure that you make an informed decision when it comes to choosing your paving type.

Uses for Paving Slabs, Suitability, & Inspiration

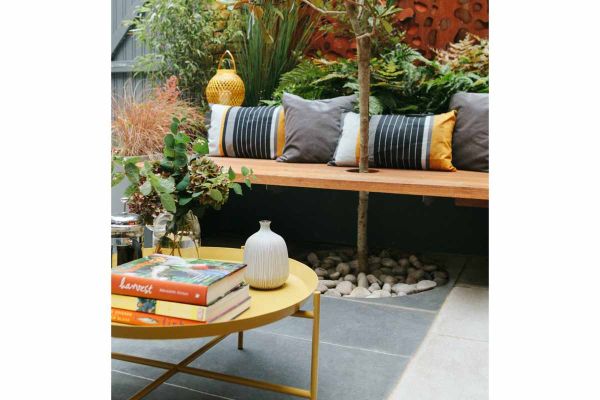

Patios: The most typical and common use for garden paving is in a terrace. Create a welcoming outdoor space with patio slabs, whether used for cooking and dining, lounging, entertaining, or all three! The right slabs can set the perfect ambiance, and give your outdoor area the perfect base, when incorporating other elements like garden furniture, planting, and ambient lighting.

Garden Paths: Use paving stones to craft charming paths that meander through your garden, enhancing its natural beauty, or create practical walkways that give you functionality and ease of movement. Whether creating a feature pathway using clay pavers, or installing stepping stones across a lawn, London Stone has a plethora of paving choices for your garden path.

Driveways: opt for robust pavers to withstand the weight and pressure of vehicles, ensuring longevity and aesthetic appeal. Whether using natural stone, porcelain, or clay paving, it is advisable to choose grey, or darker, varied colours for your driveway, as they are more sympathetic than paler tones, to tyre marks and staining.

Garden Features & Bespoke Options: Although every garden is unique, mixing materials like clay pavers and porcelain, or creating a bespoke natural stone feature, can elevate your outdoor space into something truly magnificent. London Stone offer an extensive range of bespoke paving options to help transform your project.

Steps & Copings: Most gardens navigate at least one change in level, be it a step down from a backdoor, a grand front entranceway, or raised flower beds. London Stone supply a wide range of steps and copings across the entirety of our natural stone and porcelain ranges, so you can be sure to find the perfect product to suit your style and budget. If you have the luxury of a swimming pool, our steps and copings can also be used to create a beautiful, lasting finish. Clay Pavers can also be used to create smart steps and risers, so are not limited to just being laid on the ground as paving.

Most paving types are suitable for use in all the above applications, but we have compiled this handy table so you can easily compare the diverse types of paving materials that London Stone supply, to suit your style, budget, and application.

If you are unsure of where to begin with your garden project, we have created a comprehensive portfolio of some of our favourite projects featuring London Stone paving materials. From front gardens and driveways to pocket-sized city courtyards, to vast family gardens, and even RHS show-winning designs, we have compiled inspirational galleries, bursting with take-home ideas and nifty design techniques, to whet your creative whistle.

Pricing of Paving Slabs

The cost of paving slabs can vary widely based on the material, size, and finish. Within each paving range, London Stone provides a mix of affordability. One type of paving (i.e. natural stone over porcelain) is not necessarily cheaper than another.

Imported Riven natural stone starts from just £24.00 + VAT m², with British-quarried materials at the top end retailing for over £170.00 + VAT m². Our porcelain range starts at just £27.00 + VAT m² with our Indian-sourced, Project Range, and rises to the 90.00 + VAT m² mark for our large format, Italian tiles, Sidewalk and Yard.

Other variables, such as how the product is installed, whether it requires pre-sealing, or how it is pointed, are all factors to consider. Our clay paving range sits between £70.00 and £105.00 + VAT m² but may cost less than natural stone or porcelain to install.

There are several factors at play when it comes to the differing prices of paving slabs, including: demand, ease and cost of quarrying and manufacturing, and transportation costs.

As a rule, the more processed a natural stone is, the higher the cost — i.e. riven sandstone with a hand cut edge, is cheaper to produce than a sawn-and-sandblasted sandstone with a machine sawn edge. Porcelain manufactured in India is cheaper than our porcelain slabs made in Italy.

London Stone will never compromise on the quality of our products, and we aim to keep our prices as competitive and affordable as possible for our retail and trade customers. Occasionally our prices must be raised to meet with increased manufacturing or shipping costs, but we will always do our best to reduce prices at the earliest possible opportunity.

Do My Pavers Need Sealing?

When installing outdoor paving, sealing your stone can be a good idea. Sealing paving does not make paving slabs impenetrable to dirt, but sealing can help protect your paving slabs from long term staining, weathering, and general wear, and tear.

Different types of slabs require different sealants:

Natural Stone Slabs: Applying a breathable, penetrating sealant is recommended on all sawn (smooth) natural stone. When sawing natural stone to make the surface even, the pores of the stone are opened-up, making it more absorbent to moisture, and therefore more susceptible to staining from substances like red wine, cooking oil, and leaf drop.

Pre-sealing stone helps preserve the stone's natural appearance while providing protection, and assisting you with ongoing maintenance. Some customers choose to seal riven natural stone, despite it being harder wearing than its sawn counterpart. Lighter riven slabs, such as Mint Sandstone, will benefit more from being sealed than a more forgiving stone, like Raj Green Sandstone. Sealing will benefit all natural stones laid in areas of high traffic (front paths, gardens with pets and/or children playing), if laid in shady north-facing, or damp gardens (as your paving will be more prone to algae), or where fruits and leaves drop (especially cherry, sloes, mulberry and maple).

Certain stone types — specifically Midnight Black Limestone — can fade once laid and exposed to UV rays. The fading process can be slowed by applying a colour-enhancing sealant.

London Stone provide a pre-sealing service, where we pre-seal your paving under controlled factory conditions, prior to delivery, giving you peace of mind that your paving has been protected against the elements for up to fifteen years (or five years if using a colour-enhancing sealant). We can also provide a guarantee for the sealant, available on request.

Porcelain Slabs & Clay Paving: Due to the manufacturing processes involved in these products, we do not recommend that either are sealed prior to, or after laying. Some customers choose to seal clay paving to help stabilise the jointing sand when used in applications such as a steep driveway, although this is optional.

Understanding Paving Slab Surface Finishes

Natural Stone

Excavated in colossal blocks from quarries across the globe, natural stone is then processed in a number of ways, depending on its natural characteristics as well as the desired usage.

Riven: This is the 'purest' form of quarried natural stone, in that it is naturally split along the fault lines of the stone, given a slightly uneven top surface. This type of paving slab is most found in sandstone, limestone, and slate, and lends itself to more rustic or traditional garden designs.

Tumbled: After being hand-cut, each slab is vibrated in a machine with small rocks and water to gently soften the top surface and edges. This process gently weathers the natural stone and is especially at home in projects that are looking for paving to have a slightly weathered, aged look from the moment it is laid.

Sawn: Sawn using a diamond blade for precision cutting, these blocks are machine-cut to give them a consistent, smooth top surface, giving them a more modern finish. Found across our sandstone, limestone, granite, Yorkstone and Portland products, these slabs are perfect for customers looking for a sleek finish.

Sandblasted: Abrasive sand is blasted at the sawn stone under high pressure. This process enhances slip-resistance and alters the material's overall appearance, making it particularly effective for dense, smooth stones, like Buff Sawn Sandstone.

Flamed: Particularly prevalent in granite and some sandstones, a flame is passed across the surface of the material, causing a chemical reaction with minerals within the stone, giving a slightly rougher surface finish and aiding slip resistance. Flaming can also give natural stone a slightly sparkled finished look.

Brushed: Natural stone slabs can benefit from being brushed as part of the final manufacturing process, to give an ultra-smooth finish. This is usually done after being sawn and sandblasted. All of London Stone's paving materials adhere to the British Standard of slip-rating, meaning that they are all suitable for laying outdoors in the UK and Ireland.

Porcelain

Being factory-made from natural materials, porcelain has far less surface variation to consider, when compared with natural stone. There are, however, some subtle differences in the way it can be made, which could influence your decision-making, if considering porcelain as a paving material.

As well as having a vast range of colours across our range, when moulded-and-fired, stone effect porcelain paving slabs are getting increasingly sophisticated and can possess authentic surface characteristics such as being slightly riven, to make the porcelain tiles feel slightly more natural, while wood-effect slabs have a slight timber-grain texture to give them a more naturalistic finish.

Edges And Joint Widths Laying Patterns

Natural Stone

London Stone's range of paving slabs is made up of several different edge types. Across our natural stone range, many of riven paving slabs have a 'hand cut' edge, giving a more rustic, traditional feel. Due to dimensional tolerances within the manufacturing process, the recommended minimum joint width for these products is 10mm.

Our sawn range of sandstone, limestone, and granite, and riven slate and riven limestone all have precise machine-sawn edges, offering a more modern-look. These materials can therefore be laid with a thinner 5mm minimum joint width if required, adding to their contemporary aesthetic.

Porcelain

Porcelain is a precision paving material that does not have any dimensional tolerance, lending itself to being laid with a minimal joint width of 5mm, or below.

Clay Paving

Although factory made, clay pavers do possess dimensional tolerances on each edge of the bricks (i.e. length, depth, width). We therefore recommend laying clay bricks with a 2-3mm joint.

Cleaning Your Paving Slabs

All types of exterior paving require a degree of ongoing maintenance, and your choice of paving is a significant factor in determining the level of upkeep required. With all our paving, we recommend a minimum of 'seasonal maintenance' — i.e. jet washing with detergent or another suitable cleaning chemical 3-4 times per year.

Every garden or outdoor setting is different, and factors such as usage (i.e. BBQ's and pets/children playing), the environment (i.e. fruit trees and leaf fall, or dark, shady, damp areas), and personal preference (i.e. whether you want to keep your paving looking 'just laid', or if you're happy for it to develop a patina over time) all determine how regularly, and to what degree, you clean your paving.

Exploring Different Laying Patterns for Paving Slabs

Choosing the right laying pattern for your paving slabs is crucial in defining the aesthetic and functionality of your outdoor space. London Stone's paving slabs can be laid in a variety of patterns that can be used with our diverse range of paving slabs to create the perfect look for your patio, garden path, driveway, or any other outdoor area. Here's a more detailed look at some popular laying patterns and their unique characteristics:

- 1. Random Pattern

A 'random' pattern uses a mix of different-sized slabs to create a natural, informal appearance. This pattern is perfect for those seeking a rustic, organic look that blends seamlessly with natural surroundings. It works exceptionally well with our Indian Sandstone pavers and slabs of up to four sizes, adding charm and character to smaller areas by making them appear more spacious.

- 2. Stretcher Bond

The stretcher bond, or running bond, is a classic pattern where slabs are laid in a staggered fashion, like brickwork. This pattern offers a clean, organised look that suits both traditional and contemporary designs, and is utilised with a singular sized paving slab. It is ideal for creating a structured and linear appearance, making it an excellent choice for our 900x600mm Porcelain Paving and Sawn Paving slabs. The stretcher bond pattern enhances the visual length of a space and can make it appear longer and more streamlined. This laying pattern can also be used with natural stone setts, stone pavers, and clay pavers, to create a stunning result.

- 3. Coursed Patterns

Modular, coursed patterns use a combination of different slab sizes (with one consistent measurement within every slab size used) arranged in a repeating sequence. These patterns are designed to create a harmonious, balanced look that can be tailored to suit any design preference. Often used with our sawn stone and porcelain ranges, this pattern can also be used with riven materials, and creates a cohesive, custom design.

- 4. Stack Bond

The stack bond pattern features slabs aligned in a grid, with each slab perfectly aligned with the ones above and beside it. This pattern creates a clean, minimalist look that is ideal for contemporary spaces. It is best suited for our porcelain paving and smooth Sandstone slabs, providing a sleek and orderly appearance that enhances modern garden designs and patios.

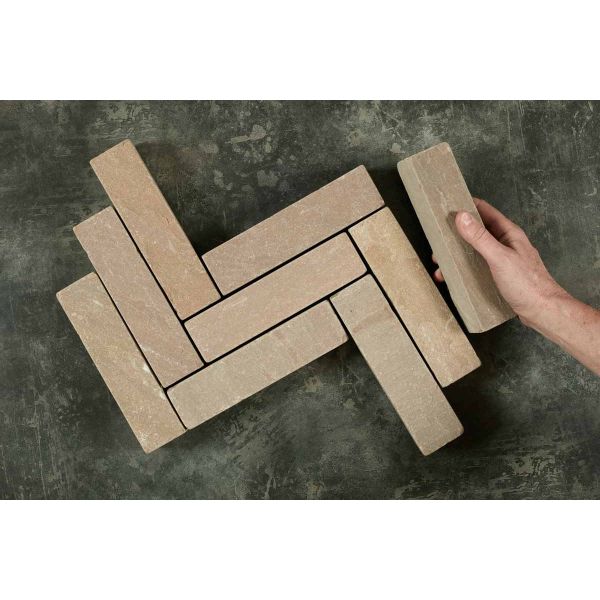

- 5. Herringbone

Herringbone is a timeless pattern that involves laying slabs in a zigzag formation. This design is particularly strong and durable, making it suitable for high-traffic areas such as driveways and pathways. The intricate interlocking pattern adds a touch of elegance and complexity, which can be beautifully achieved with our Clay Pavers, rectangular Stone Setts, or Stone Pavers. Herringbone is available in both 45-degree and 90-degree angles, each offering a distinct look.

- 6. Basket Weave

The basket weave pattern consists of pairs of slabs laid horizontally and vertically to create a woven effect. This pattern provides a classic, textured look that adds visual interest to patios and garden areas. Used primarily with our more rustic-looking clay paving and stone pavers, this pattern offers durability and a sophisticated finish that especially complements traditional settings.

Selecting the Right Pattern for Your Project

By selecting the right pattern, you will maximise the visual and functional impact of your paving slabs, creating an outdoor space that is both beautiful and practical.

When choosing a laying pattern, consider the following factors:

Space Size and Shape: Patterns like stretcher bond and coursed patterns can make expansive areas look more coherent, while random layouts and herringbone patterns add interest to smaller spaces.

Aesthetic Preference: Decide whether you want a traditional, rustic look, or a modern, clean finish. Patterns like random layout and basket weave offer a classic appeal, while stack bond and stretcher bond patterns are perfect for contemporary designs.

Functionality: For high-traffic areas such as driveways or pathways, choosing durable patterns like herringbone or a random pattern will provide additional strength and stability.

Laying Methods and Grouting

London Stone advocates using skilled professionals for garden design, installation, and maintenance. If you do not already have a trade professional lined-up, our Connect tool can put you in touch with registered specialists.

Natural Stone, Porcelain, and Clay Paving can be installed in several ways, depending on the application (i.e. a porcelain driveway will be installed differently to a clay paving patio). Head over to our YouTube playlist where you will find a comprehensive list of installation videos.

Here are some handy tips to help you better understand how to install our paving products:

- Preparation — ensure that paving is installed on a solid, excavated sub-base, that has been compacted using a plate compactor. A sub-base for a driveway needs to be deeper than that of a patio.

- Mortar Bed — exterior paving slabs should be installed on a full mortar bed, made up of sharp sand and cement or on a concrete base (for porcelain and natural stone), or on a sand screed (for clay pavers). Never lay paving slabs using a 'dot and dab' method, as this will lead to irreparable issues.

- Natural Variation & Pattern Repeat — to ensure the best finish, make sure that natural variation (when using natural stone or clay paving) is spread evenly across your paved area, or if installing porcelain slabs, ensure that patterns are not repeated too closely.

- Slurry Primer — if laying porcelain slabs, or less porous natural stones such as limestone, granite, and slate, be sure to apply a priming slurry to the back of the slabs, to ensure that they adhere to the mortar beneath.

- Sealing — pre-sealing slabs prior to laying them is advisable over applying sealant once the materials are laid. To seal stone paving slabs, they need to be completely dry (and then remain dry after applying it, while it cures), which is difficult to control. Pre-sealing paving prior to laying will also help you to remove any marks or stains caused during the installation process. Never seal the bottom of paving slabs, as it will affect their ability to bond with the mortar it sits atop.

- Drainage — unless your paving has an adequate natural run-off, drainage is likely to be required. London Stone supply a wide range of drainage options to complement your paving slabs.

- Pointing/Grouting — once slabs are laid and the bedding mortar is set, fill the joints with a pointing compound. This not only secures the slabs in place and prevents weed growth but will also leave you with an attractive finish. This helpful blog will help you choose which grouting product suits your paving slabs - and your style and budget - most appropriately.

We have also compiled a comprehensive list of frequently asked questions about the installation of our exterior paving products.

FAQ's

Are your materials ethically sourced?

London Stone is committed to ethical sourcing. We ensure that our natural stone products are sourced from suppliers who adhere to fair labour practices. Our dedication to ethical practices extends to every aspect of our business, from sourcing raw materials to delivering the final product to your doorstep. We believe in creating beautiful outdoor spaces while maintaining a responsible approach to the environment and communities involved in our supply chain.

Do You Have Showrooms Where I can View Materials?

London Stone has a nationwide network of showrooms, where visitors can view our materials in situ. Our showrooms are designed to inspire and assist you in making the best choices for your outdoor projects. Across our multiple locations, you can explore our extensive range of paving slabs, composite decking, vertical solutions, pergolas and garden planters, and more. Our friendly, knowledgeable staff are on hand to provide expert advice and help you visualise how different materials and patterns will look in your space. Visiting a showroom gives you the opportunity to see the quality of our products up close and make informed decisions.

You will never experience a 'hard sell' approach at our showrooms. You will encounter a relaxed environment, including complimentary refreshments, and free customer Wi-Fi.

What's The Ordering Process and Your Lead Times?

Ordering from London Stone is straightforward and designed to ensure you receive exactly what you need for your project. Here is how it works:

Calculate Wastage: We recommend ordering an additional 10% of materials to account for wastage during cutting and laying. This ensures you have enough product to complete your project without unexpected delays.

Place Your Order: Easily place your order online, over the phone, or in one of our showrooms.

Delivery: Choose your preferred delivery option, and we will ensure your materials arrive on time and in excellent condition. London Stone offer next day delivery on many of our items, subject to availability, if ordered before 1 p.m. If you choose to have your natural stone slabs pre-sealed by us, that usually takes around two weeks. The lead time for bespoke orders can change, depending on the size and complexity of the order, stock availability, and demand for the service. Most bespoke orders take around 4 weeks to be delivered, from the time of order.

What Is Your Returns Policy & What If I Have Any Unused Goods?

We understand that sometimes plans change. Our returns policy is designed to be fair and accommodating:

Unused Goods: If you need to return unused goods, you can do so within 14 days of receipt. The items must be in their original condition and packaging.

Restocking Fee: A 20% restocking fee applies for returns for trade clients. We do not charge a restocking fee to retail customers.

Bespoke Orders: Custom-cut or bespoke items are not eligible for return. We advise confirming the details of such orders carefully before finalising.

How Can I Contact London Stone?

We are always here to help you with any questions or concerns, and we offer a number of ways to contact us:

WhatsApp Chat: The quickest way to contact us is via WhatsApp, where you can reach out to our sales team, customer service team, transport, and production departments.

Online Chat: Use our online chat feature for immediate support and quick answers to your questions.

Phone & email: Speak to us over the phone by calling 01753 212 950, or email info@londonstone.co.uk for answers to your questions.

Showrooms: Visit one of our showrooms to speak with our experts in person. You can find your nearest showroom here.

London Stone are dedicated to ensuring that every customer has a positive experience. From ethical sourcing and expert advice to flexible delivery and easy returns, we strive to provide a service that meets and exceeds your expectations. Explore our extensive range of products and start planning your perfect outdoor space with us today.

/filters:quality(55)/mediadev/media/product-swatches/FPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/EBLPa.jpg)

/filters:quality(65)/mediadev/media/product-feature-banners/feature_banner_delivery.jpg)

/filters:quality(55)/mediadev/media/product-swatches/DGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/VGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/HSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AnPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGCB.jpg)

/filters:quality(55)/mediadev/media/product-swatches/LGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCAADM.jpg)

/filters:quality(55)/mediadev/media/product-swatches/JBPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCBSPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TKGSPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCASGM.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AGLP.jpg)

/filters:quality(65)/mediadev/media/product-feature-banners/feature_banner_showroom.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ABSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CoPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FBPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AYLPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/DSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/YPP.jpg)

/filters:quality(65)/mediadev/media/product-feature-banners/feature_banner_paypal.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/LBSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/EBLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGDA.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BSP.jpg)

/filters:quality(65)/mediadev/media/product-feature-banners/feature_banner_guarantee.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BSPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGGA.jpg)

/filters:quality(55)/mediadev/media/product-swatches/GBP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/JBLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/RPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TMSPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/GGLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ArPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGOE.jpg)

/filters:quality(65)/mediadev/media/product-feature-banners/feature_banner_pack.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ABPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ACSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BGP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/RGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TRGPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGAN.jpg)

/filters:quality(55)/mediadev/media/product-swatches/MBLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCABE.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/JGLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BuSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TMSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCMISS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SiCPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/KBrLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/HSPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/RGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGMO.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AYLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FWPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCARB.jpg)

/filters:quality(55)/mediadev/media/product-swatches/MMSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BBSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCASPA.jpg)

/filters:quality(55)/mediadev/media/product-swatches/MSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BBYP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCASGR.jpg)

/filters:quality(55)/mediadev/media/product-swatches/AGLPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/PPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCASE.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TRGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/HeSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TBSPa.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TKGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCRPS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/GPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCMSCI.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGSS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCARC.jpg)

/filters:quality(55)/mediadev/media/product-swatches/NPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CrPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/StGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CDSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TBPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCBGS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/DGGP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SKPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SGGP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/KGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/VPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCSTGRPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CiPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCRGSCI.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGRA.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FrGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/GSPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCDGGPLA.jpg)

/filters:quality(55)/mediadev/media/product-swatches/RSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/UGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCAWIN.jpg)

/filters:quality(55)/mediadev/media/product-swatches/RYP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/PCPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCADE.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCBGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FSPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGCP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCGYP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCACP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SGGHS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/GSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCRGSS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCHPS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/CorPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCDUCP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCBERCP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/VBPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCAAL.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCPGPS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCLGRPS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/KPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCGLM.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCABSS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKCVU.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TDPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGVE.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCAAM.jpg)

/filters:quality(55)/mediadev/media/product-swatches/FDPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCREPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SCPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/JGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCSGGSS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGL.jpg)

/filters:quality(55)/mediadev/media/product-swatches/PGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/BBPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGRO.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCCHAPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/SWPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCAWE.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGSCI.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGB.jpg)

/filters:quality(55)/mediadev/media/product-swatches/MGPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCARCP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCMBLS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCABSCI.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCTKGSS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/TBSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCPGRPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/KBlLP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCKGLU.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ChPP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCSGPS.jpg)

/filters:quality(55)/mediadev/media/product-swatches/KGSP.jpg)

/filters:quality(55)/mediadev/media/product-swatches/ECCTMSS.jpg)